Stepper motors are ubiquitous. From clocks, to 3D printers, to CNC mills. From split flap displays to spaceships. They are everywhere. The nature of their operation makes them the ideal option for many different systems that can’t (or don’t want to) afford complex electronics for closed-loop motion control but still need positional accuracy. They are great, their sound is awesome, and you can even make them sing. But when it comes to selecting one for your application, finding a trusty vendor, and then procuring your motors, it can be a daunting task.

Part of my daily work is dedicated to engineering the DIWire, the desktop CNC wire bending machine, and over the past the months I spent quite some time redesigning its power train. When we started this project we thought we new everything there was to know about steppers, but we were so wrong.

This series of posts therefore aims to be a recollection of lessons learned for future reference and for anyone else out there going through the process of selecting a stepper motor (good luck!).

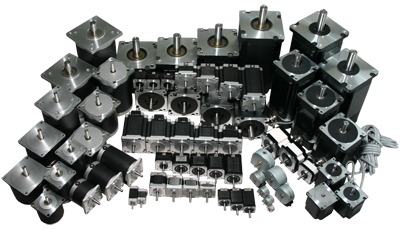

Steppers come in many different sizes, package types, wiring types, torque ranges, step angles, accuracies, gearboxes, shaft types, etc. Canned, hybrid, NEMAs, unipolar, bipolar, geared or ungeared. Single shaft, double shaft, hollow shaft, single-double-triple stacks… whew! And then you look at the catalogs and they are hundreds of pages long! So… How do you choose?

Well, the easy way is to have a process. So in this series of posts I will cover my 10 step ultimate stepper motor selection guide (USMSG) in detail. Following these steps and putting some thought on your design specs should point you in the right direction.

The Process

As I mentioned above, the process I ended up developing/following for properly selecting and procuring the stepper motors for my application is comprised of 10 steps. Some of them will be obvious, some others wont. But one thing we learned was that even those steps that can be seen as “obvious” have to be taken care of, otherwise it will hurt later on in the process. So, with that being said, these are the 10 steps for a successful and (almost) pain-less selection of a stepper motor:

- Define your system requirements (set the spec)

- Determine the pull-out torque requirements

- Determine the accuracy

- Evaluate the torque curves (and vendors) of your potential motor

- Define the drive train

- Add a gearbox

- Spec your motor driver

- Get some samples

- Test, test, test!

- Integrate, test and validate

As you may imagine, this was originally quite a long post, accurately reflecting my experience with this process. So, since I’m adding as much info as I can so it all gets properly captured, I’m splitting this guide in a series of posts so it’s not too heavy of a read. Just click the links above to read the full series.

And thanks for reading! Hope it’s helpful. Let me know what you think in the comments.

Oscar

Disclaimer: I’m putting “ultimate” in the name because I’m writing everything I know about steppers. It doesn’t mean this is the one and only guide. Any stepper vendor, Wikipedia or even Google should have good info. But since none of that has been distilled down to something manageable, this is my attempt at a comprehensive compendium of both the available and non-available info out there.

1 Comment on “The Ultimate Stepper Motor Selection Guide”